FLOW SCREED SOUTHWEST

Approved installers of Aeromix covering Devon, Dorset, Somerset and Wiltshire

WORLDS LEADING EPS FLOWING INSULATION 0.037W/MK

Market leading EPS Bound flowing insulation 0.037 W/mk

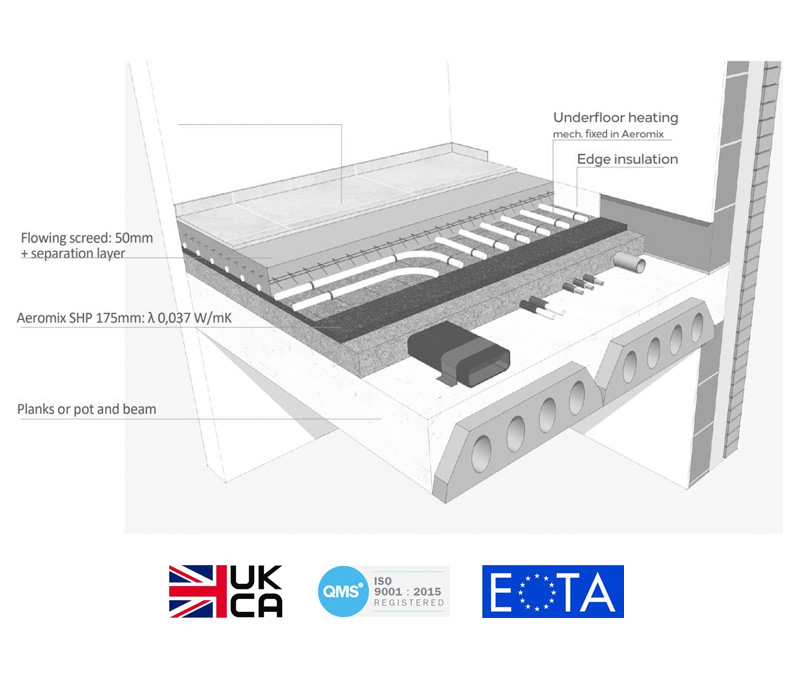

Aeromix ~0.037W/mk is market leading EPS cement bound flowing insulation. Aeromix is a mixture of EPS, Cement, Aerogel and water. Aeromix ~0.037W/mk is covered with EOTA and UK/CA

Aeromix – Key Features